Smart Dongle

A compact wireless development board to build your own smart home devices.

2021

Ordinatra

Client

Year

Brief

To produce an enclosure to house the latest version of Ordinatra’s wireless connected development board. The solution needed to:

Fit the new PCB and allow access to key components

Enable easy and tool free user disassembly

Embody an exciting, novel, aesthetic

Accommodate potential future expansion projects

Allow for viewing of the onboard LED

Outcome

Created a market ready product that was manufactured at scale. The solution was carefully designed to remain cost effective, while offering an effective snap fit assembly solution and an eye catching fractal aesthetic.

Generated key marketing media to help communicate the full scope of features and product benefits. This supported the launch of the first production batch in early 2022.

Key Design Features

Tool free snap-fit assembly/disassembly

Unique and exciting fractal design

Matching USB to USB-C convertor casing

Optional antenna for extended range

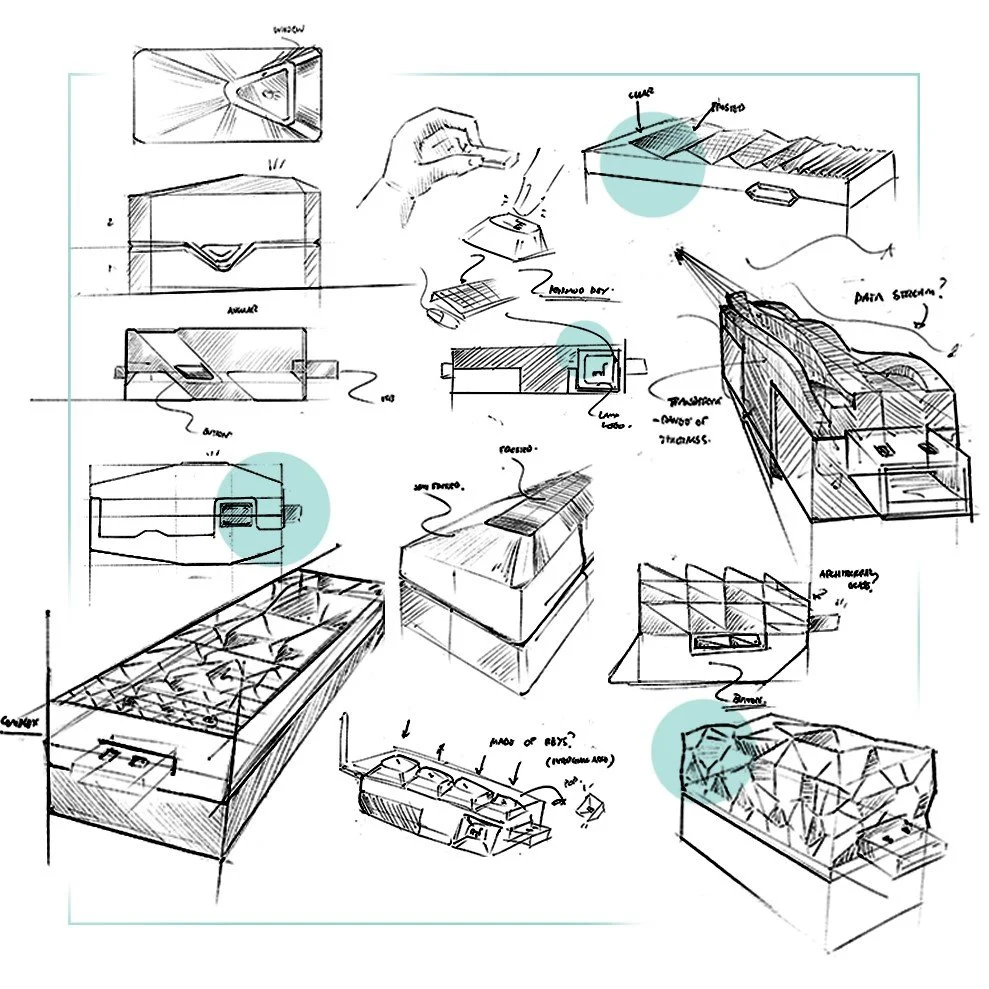

Capturing a Unique Aesthetic to Increase Product Value

Taking inspiration from the flow of digital information, we conceived a tactile fractal design for the outer casing. Marrying this design with a translucent plastic created a disrupted view of the electronics within, helping the product to stand out from its competitors.

In order to ensure the final product would operate alongside existing USB devices, it was important that the total package volume was minimised as much as possible. We managed to achieve this whilst implementing the eye catching design that makes the product so unique.

Understanding User Behaviour to Maximise Functionality

At the core of the product offering was the idea of tinkering and adaptability. The PCB was built to accommodate this, offering antenna connectivity, multiple external ports, and a complementary USB-C adapter. It was imperative that users could easily access the many features at their disposal.

Robust snap fit wings were integrated into the packaging, allowing tool free disassembly at a moment’s notice. The wings sit discretely at the side of the product and ensure the electronics are safely housed when closed. Considering user behaviour from the outset has ensured that the product meets all usability requirements without compromise.

Using Manufacturing Experience to Ensure Product Quality

Prior to manufacture, we completed multiple tolerance stack analyses to mitigate potential production issues. We then performed quality assessments on initial production batches to fine tune the plastic colour and translucency, and the position of critical mating faces.

The implementation of our production experience in the latter stages of this project meant that only two sample batches were required, and the product was ready for market on schedule. Managing our production network efficiently also reduced the number of tooling modifications required, and kept project costs within scope.