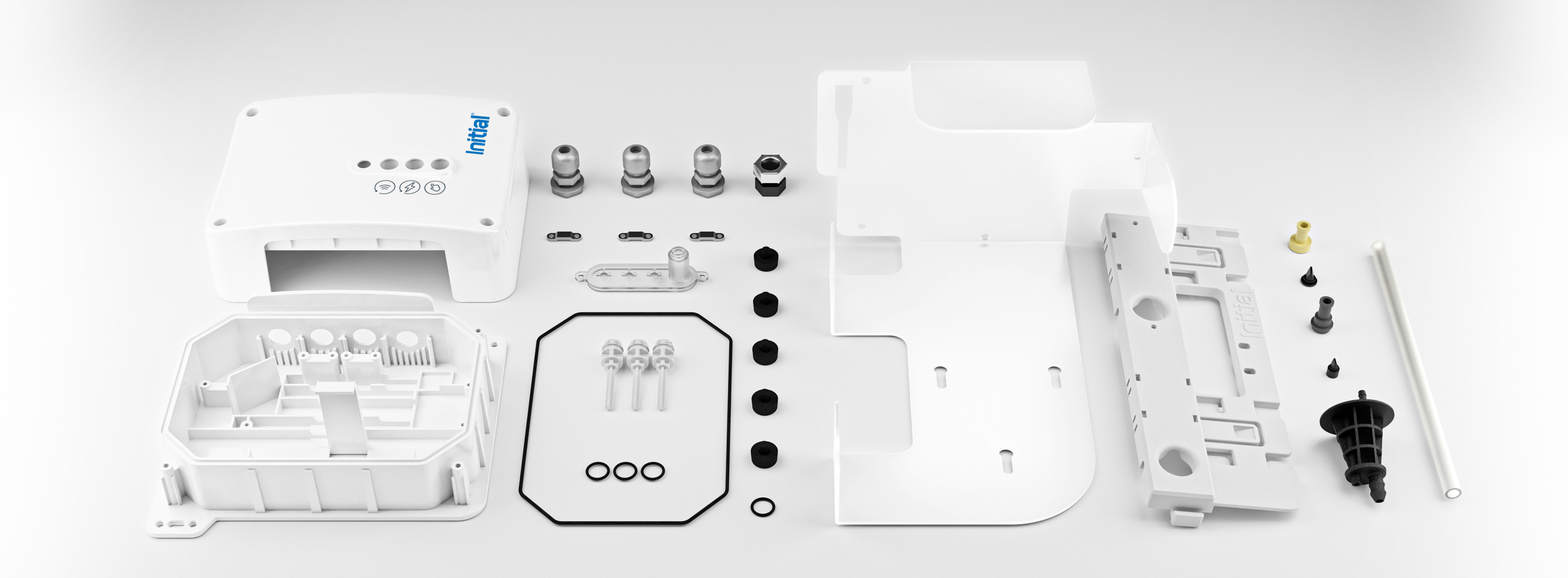

Rapid Hygiene System

An internet connected hand washing system for public and commercial washrooms

Client

Year

Brief

2020 - 2021

Rentokil Initial

Redevelop the existing hand washing system, improving functionality and scaling the business to mass manufacture. To provide an effective solution that suited the business requirements, the products needed to:

Vastly reduce the unit cost.

Accommodate existing parts and developed electronics.

Improve system efficiency and efficacy.

Withstand a variety of harsh environments.

Facilitate easy installation and ongoing maintenance.

Outcome

Designed, tested, and brought to manufacture a cohesive suite of products that reduced the total unit cost by 85%. Each solution offered improved functionality, a reduced part count, and embodied the Signature Initial styling.

The updated products replaced their predecessors in the field, and now operate in multiple washrooms across the UK.

Key Design Features

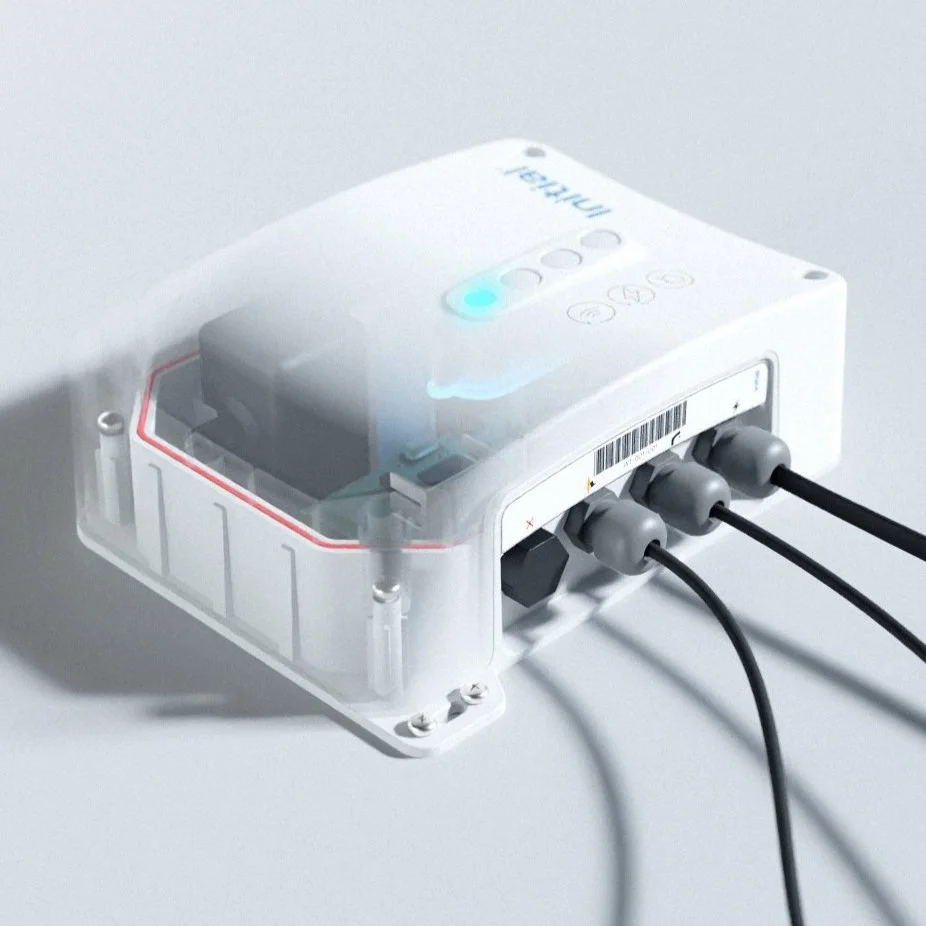

IP68 rated housing.

Fixing free assembly between sheet metal and plastic components

Simple three button interface for setup and customisation

Fits any commercial soap bottle

Robust construction for durability in extreme conditions

Economically dispensed luxurious foaming soap

Creating a Low Cost, Mass Manufacture Solution

The original set of products were costly to produce and optimised for small batch production. Considered design decisions ensured the refreshed offering was appropriate for mass manufacture, reducing the total unit price across the range by 85% as a result. A cost reduction of this size strengthened the business case for the project and helped our client to launch the first batch on schedule.

Originally, the soap bottle holder was a hand welded plastic fabrication. The redesigned proposal comprised a bent sheet metal part and a single injection moulded component. This solution improved the quality and durability of the part while also ensuring that the product was scalable and suitable for long term production.

A Simple Solution Built for Longevity

Once installed, these products will stay in the washroom for an extended period of time undergoing regular maintenance, often by people with a heavy hand. It’s vital that this process is simple and effective. We took insights from real world use cases, and used this to inform key usability features. The distinct mounting tabs on the water enclosure are an understated but effective way to mount the product without requiring instruction or experience.

Throughout development, parts were tested to ensure strength and durability. The Water Enclosure has been designed and tested to an IP68 water resistance rating, the highest available. This is a feature that will ensure its continued function, even in wet washroom environments that are prone to flooding and leaks.

Working With an Established Brand Identity

The refreshed range needed to integrate seamlessly with Initial’s existing Signature collection. 3D visualisation and hand rendered concepts were used as a way to explore ideas, and detailed brand guidelines were used as a reference for colour, form, and layout. The final set of products emphasised clean curves and the pure white colourway in order to match the Initial identity.

Full brand cohesion extended further than physical product design in this project. Labels and icons were created from scratch, following the brand guidelines in detail. These assets were used to create pad prints and information labels on the exterior of the water enclosure, and formed an important part of preserving the Initial identity.

Marrying Intelligent Design with Existing Infrastructure

Each product in the range works as part of a wider hygiene system. We designed the individual elements to have the flexibility to work alongside a range of equipment and consumables. The family of products can incorporate different faucets, soap bottles, and water systems to be fitted in any commercial washroom.

The bottle pickup bung uses a tapered array of flexible ribs to ensure a variety of soap bottle diameters can be used in the system, without affecting performance. This solution is incredibly effective but is also simple, and only requires a single, well designed, part to offer full flexibility. Throughout development we made sure that the desire for adaptability was complimented by the need for a cost effective solution, viable for long term production.