Flush Plate

A premium wall mounted public toilet flush plate.

Year

Client

2020 - 2021

Duten

Brief

Develop a high-quality metal replacement to the plastic flush plates offered by the market leaders of in-wall toilets. The core requirements for this project were:

Can be retrofit to Geberit and Siamp in-wall cisterns.

High quality metal in different colour finishes.

Simple installation and cleaning.

Reliable and satisfying flush mechanisms.

Outcome

Developed, tested, and engineered a complete flush plate system. Produced several iterations of full scale prototype which were used to develop, communicate, and test the design.

The project was taken through to manufacture through our engineering, with complete technical documentation and drawings produced. We supported the client to discover appropriate production partners and obtain manufacturing quotes.

Key Design Features

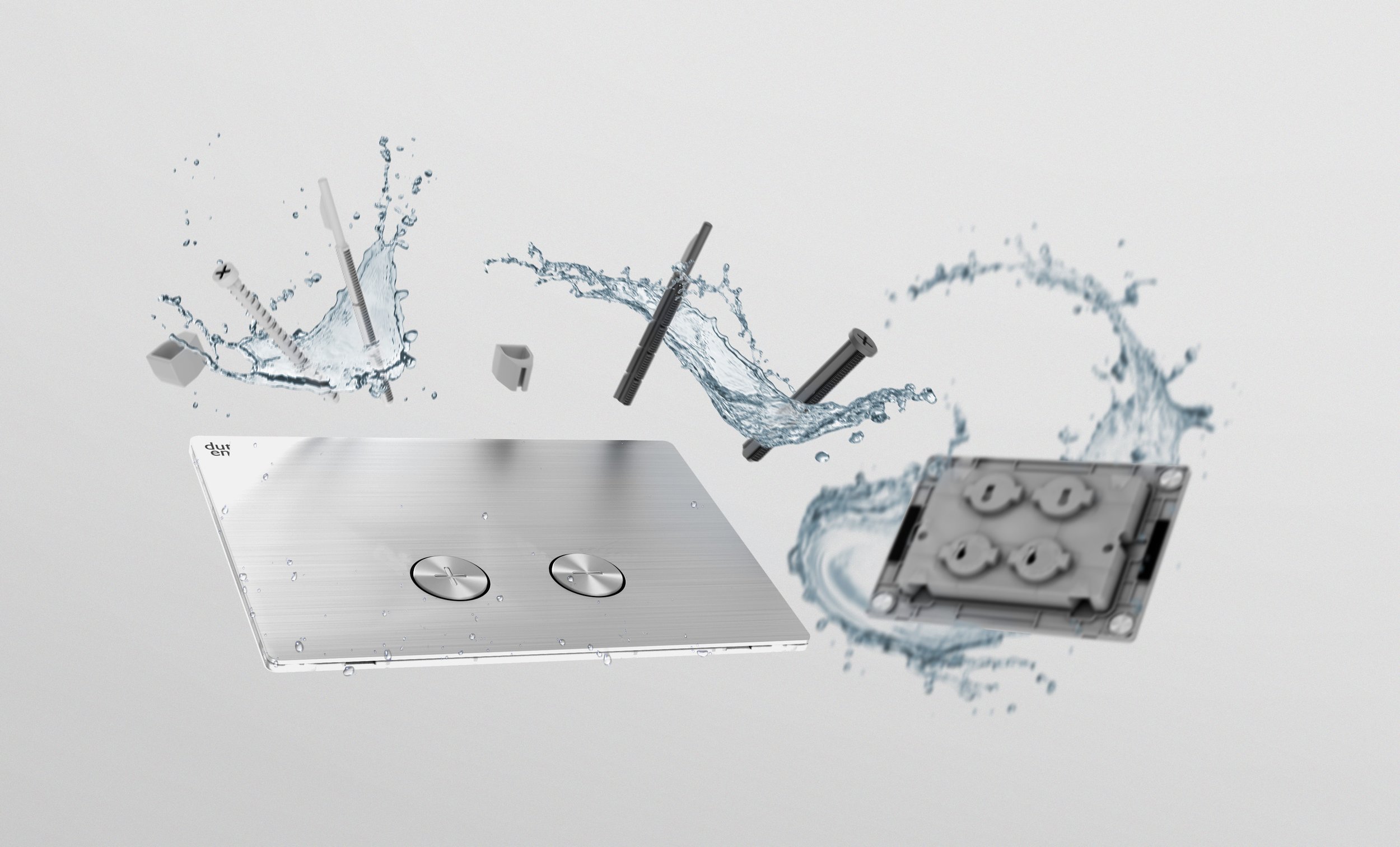

An innovative reversible frame to mount to two different cistern types.

Simple colour coded mounting accessories for quick installation.

Magnetic front for fixing-free aesthetic.

Metal front with PVC coating for a durable finish in different colours.

"Nyker has successfully developed and launched the platform that has helped increase and supply our client's projects. The team has communicated well through email to provide progress updates and the status of the partnership. Their ability to create optimal solutions is impressive.”

Craig Tennent, Duten Co-Founder

Designing for Variable Systems and Installation Environments

Although this flush plate looks simple on the outside, it needed to accommodate a vast number of installation types. Firstly, the device must mount to two completely different cisterns sold by the market leaders – Geberit and Siamp. These systems have different mounting positions and flush mechanisms. Beyond this, we needed to account for different wall thicknesses and types.

These variations pushed us to develop a novel system with a wide range of mounting flexibility. We were able to achieve this through the cleaver design of a single rear plate, which can be rotated to mount in either system.

Testing our Designs with Prototypes

Throughout the development of this flush plate we validated our mechanisms with prototypes we 3D printed in our workshop. This gave us quick and cost effective feedback on any modifications we made to the fit and function of parts.

Towards the conclusion of the project we then worked with our establish supply network to build several full size prototypes from representative materials. These both looked and functioned like the final product and were used by Duten to review, test, and market the product.

Bringing Contemporary Designs to Everyday Environments

There are limited options for high-end flush plates on the market, with existing solutions often made from cheap, plastic parts. For boutique bathrooms, this can stand-out amongst expensive washroom fittings and furniture. We elevated the Duten product through use of premium materials and precision engineering.

We designed the cover of this Flush Plate to be made from a specific grade of magnetic stainless steel so it can be fixed to the front of the mechanism without any visible fixings. We then apply a Physical Vapor Deposition (PVD) coating, which protects the surface from scratching and offers a wide range of attractive colour options.